One area that can help stabilize costs, increase efficiency and quality is with produce. Our sales director, Scott Bricker, shares some of his years of insight working with national restaurant chains on this very issue.

Fresh Cut

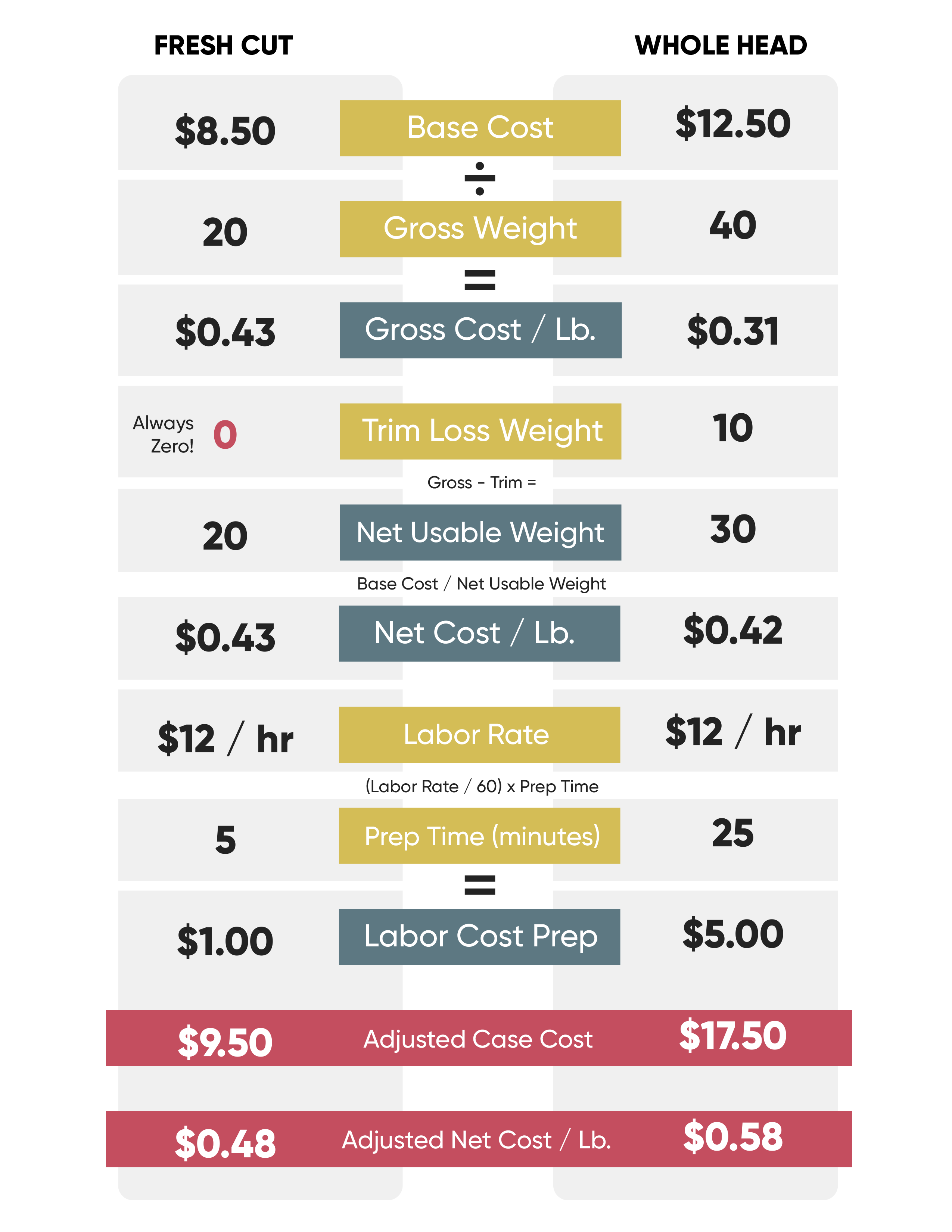

When it comes to produce, there are a couple options on sourcing. It is pretty common to go with a commodity program, and in the case of lettuce or cabbage, whole heads are packed directly into a carton in the field and sent to a warehouse to be cooled and shipped out. When restaurants receive it, the kitchen staff washes and chops the product.

When it comes to produce, there are a couple options on sourcing. It is pretty common to go with a commodity program, and in the case of lettuce or cabbage, whole heads are packed directly into a carton in the field and sent to a warehouse to be cooled and shipped out. When restaurants receive it, the kitchen staff washes and chops the product.

Price for carton lettuce fluctuates with the market and that fluctuation can happen weekly, bi-weekly, or monthly. The same goes for yield. It is a moving target that is hard to repeatedly hit with consistency because of the unpredictability of crop yield. Restaurants are left with the question of how much usable product they are paying for since price is based on the entire head and not the usable portion.

We have helped many customers stabilize this variable by going with a fresh cut program. The price is fixed and is based on 100% usable product, so there is no guessing on price and yield. Product is also cut to the restaurant’s specs and processed so waste is minimized. With the continuous fluctuation of price now out of the equation, restaurants can better budget produce spend.

Restaurant operators that move to a fresh cut program are also saving time and cost associated with labor in processing, which allows them to redirect their staff to more beneficial areas. This makes operations efficient with increased levels of food safety and consistency.

Proper Handling

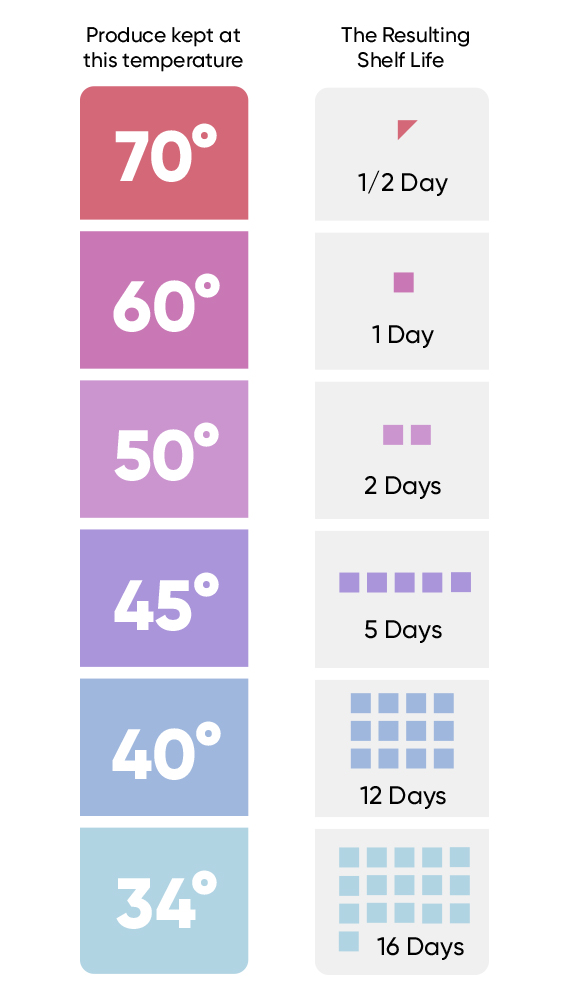

Proper handling is the first step to reduce spoilage, and spoiled produce is product restaurants are not making a profit on. The key to this is awareness and training of cooling requirements by all of the kitchen staff.

Proper handling is the first step to reduce spoilage, and spoiled produce is product restaurants are not making a profit on. The key to this is awareness and training of cooling requirements by all of the kitchen staff.

The worse offender is simply leaving produce sitting in places where it is not continually kept cooled. When shipment comes in, kitchen staff must understand it should be immediately refrigerated. For every thirty minutes these items are kept at a temperature over 40 degrees, a day of shelf life is lost. This is critical for leafy greens and any item that has been cut.

Placement of your produce in the cooler is also critical. Leafy greens and fresh cut always goes to the coldest part of the cooler, in the back and on the floor, and never near the doors where the temperature fluctuates every time the cooler is opened.

One other thing is to make sure is that product is tracked and rotated. Use older product first, and rotate older product to the front and newer to the back so there is no confusion when staff goes to grab product.

Offset Labor Concerns with Efficiency

Navigating finding, retaining, and paying for labor can be a bit of a headache in all the things restaurant operators have to consider on a daily basis. In the area of produce, there are a few tricks of the trade to make restaurant operator’s job a bit smoother. It starts with removing the questions of yield and price with the stability and consistency of a fresh cut program. It continues with increased efficiency back of house so labor dollars are not spent on chopping and washing, but on customer satisfaction. It is supported by staff training so all are aware of the link between cooling and shelf life, so product is not wasted.

If you would like to know more or have an assessment of your produce programs, our team is just a call or email away and love helping you find efficient solutions for your kitchen operations.