Published on Modern Restaurant Management

There are many things on any restaurant operator’s plate; they are running a multi-faceted business with concerns from overhead, operations, customer satisfaction, sourcing, food safety, and cost of goods.

Many owners and operators can stabilize all these variables by going with a fresh cut program. The price is fixed and is based on 100 percent usable product, so there is no guessing on price and yield. Product is also cut to the restaurant’s specs and processed so waste is minimized. All of this is done in environments with food safety in mind.

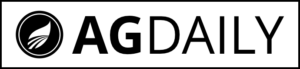

Fresh Cut Increases Food Safety

Fresh Cut Facilities Undergo Rigorous Safety Certifications and Audits

The washing and cutting of the product is done in a controlled facility that undergoes daily sanitation, rigorous audits and certifications.

Reduced Handling means Better Sanitation

From the time produce is on a wash line and bagged, to the time your kitchen staff opens the bag, fresh cut product is not directly touched. You remove the ambiguity of when and where product was handled after whole product leaves the field.

Reduced Handling means Reduced Chances of Cross-Contamination

The processing lines fresh cut product travel on are dedicated to fresh produce. We know once product is bagged and the integrity of the bag is maintained, there is no cross-contamination going on. This also prevents cross-contamination happening on a cutting surface that may not be dedicated to produce or was not thoroughly cleaned and sanitized.

Less Risk for Injury

Because product is cut and ready to serve, you take away the potential for injuries happening as a result of chopping product with sharp blades.

Fresh Cut is all About Consistency

Year-Round Consistency of Quality

One of the primary benefits a fresh cut program brings to the table is consistency. With fresh cut, you won’t cut into a head of lettuce and discover issues. You receive 100% usable product.

Year-Round Consistency of Supply

Sometimes grower’s supply is prioritized to commodity programs and the result is inconsistency with some fresh cut programs. Our fresh cut supplier only does fresh cut, so supply is never diverted away to a commodity program and is 100% sourced for their foodservice customers.

Consistency in Product across Supply Chain

The consistency in a fresh cut product is seen throughout the supply chain. All product goes through the same standardized production and controls time and time again. As soon as product is bagged, customers know what they are getting, how much they are getting, when it was cut, how long it will last, and the level of quality to expect.

More Stability with Fixed Pricing

Fresh cut programs provide fixed pricing, which takes you out of a fluctuating commodity market. We find that stability positively impacts the bottom line in restaurant operations.

Consistency in Front of Customer

Because cutting fresh product is done in a processing facility, product will not deviate from the cut that is specified for the order. For restaurants with multiple locations across a large geographic area, this ensures product will always be the same cut, without the variation that comes from multiple teams cutting to spec.

Fresh Cut Increases Operational Efficiency

Fresh cut has Guaranteed Case Weights

When you are receiving a fresh cut product with 100 percent yield, you know how much you are getting regardless of the variables that impact bulk produce throughout the year. This makes planning your purchase easier and helps with efficient use of product with less waste.

Predictable/Accurate Number of Portions

Knowing there is little variance to the product you’re receiving, the number of portions you can use per bag is much more accurate and predictable.

Clearly marked manufacturing dates to help control rotation and quality

Not only do you know how much product you are receiving with fresh cut, but you know its shelf life. Combined with proper rotation of product, you are able to boost efficiency in use of a fresh product all the while reducing food waste with spoiled product.

Easier to Inspect When Receiving and Prior to Use

Because all of the usable product is visible with fresh cut items, it is easier to inspect quality when receiving or prior to use. Again, there is no guessing what you’ll find when you cut into whole product.

Increased Product Uniformity and Plate Presentations

For restaurant chains, fresh cut ensures uniformity in cut and presentation of product across a large geographic area, because it is cut to your spec before it arrives in store.

Fresh Cut is Sustainable

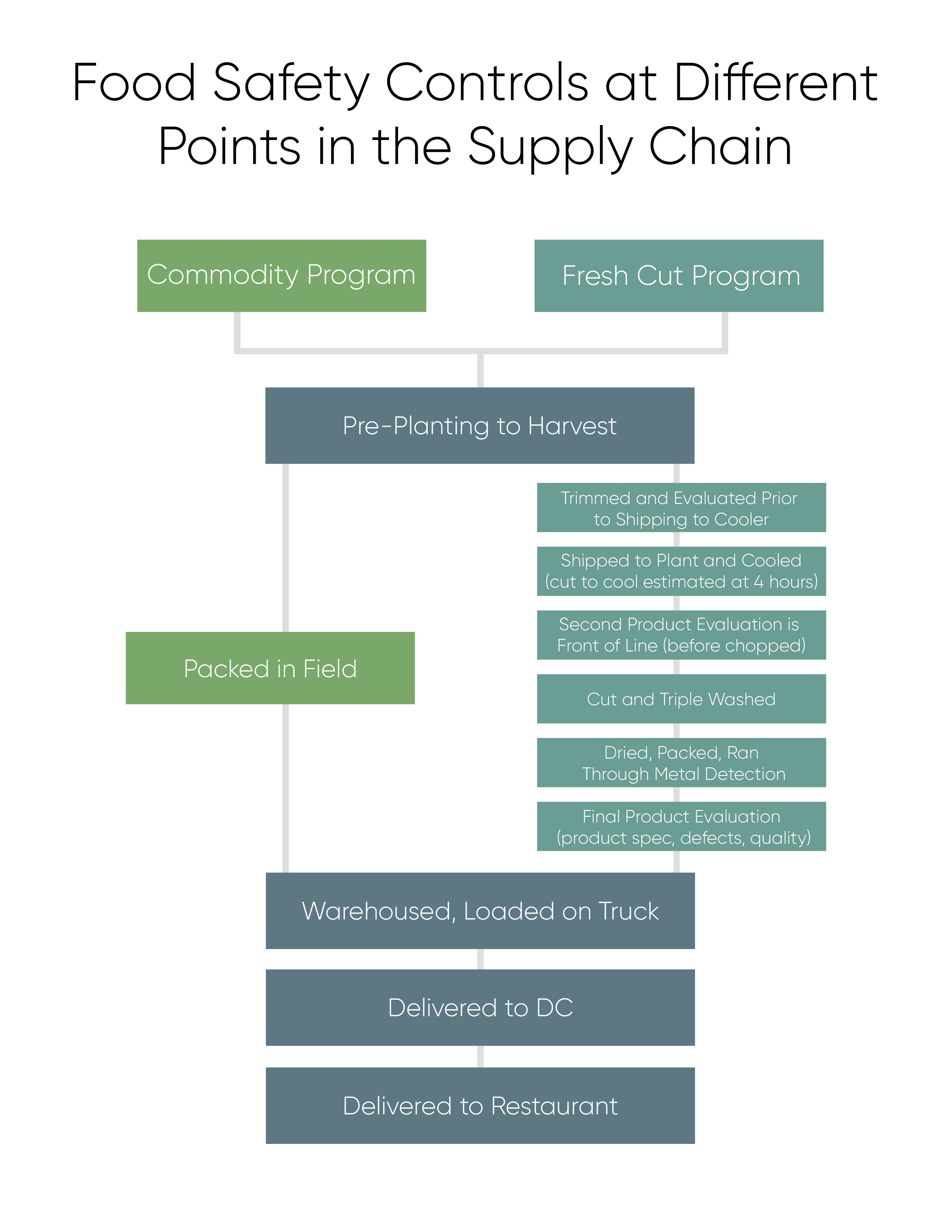

Reduced Disposal/Waste Cost

A big topic in the industry is waste, and what do you do with the unusable portions after chopping whole product? The processor handles the unused portions and disposes of it responsibly. Some producers send unused vegetable portions to compost and some convert the waste into energy used in the facility.

Efficient Operations

We know fresh cut saves time, but there are many areas where fresh cut producers are always looking to be efficient with resources. Water is used in a reverse cascade so spent water is part of the preliminary rise of product and the final rinse is the cleanest water.

Smaller Shipments, Smaller Environmental Impact

Because only usable portions are packaged, you are maximizing the amount of product that can go on a pallet. This maximizes the truck loads that are transporting the product, and with that efficiency, there’s a reduction of carbon emissions and fuel consumption from the trucks. Maximizing loads also helps offset rising shipping costs.

Fresh Cut Helps Stabilize Costs

Easier to Plan Budget and Supply

Because there is more consistency with a fresh cut program, variables like product yield, case weight, and pricing, that take time to account for, are now consistent metrics.

100 Percent Yield

There is no waste with fresh cut because it has already been removed and you only receive usable product. Your yield will always be 100%.

Increased Shelf-Life/Quality

The key to long shelf life is by cooling the product as quickly as possible after harvest. Items that are going to be processed are taken to the facility within hours and cooled. The markings on the package tell you exactly when it was processed, so you are never guessing on shelf life. This results in product that has ample shelf life compared to the unknown variables you may find with whole product.

Reduced Disposal/Waste Cost

There are costs involved with disposal of unused product that is factored into operation costs. Part of fresh cut processing is disposal that is environmentally friendly, with the costs absorbed by the facility and not your restaurant.

Less Product, Less Chilling

Fresh cut produce takes up less space allowing more room in the cooler and efficient use of space and energy. Why take up valuable space with a bulkier item that is not 100% usable when fresh cut saves space and energy?

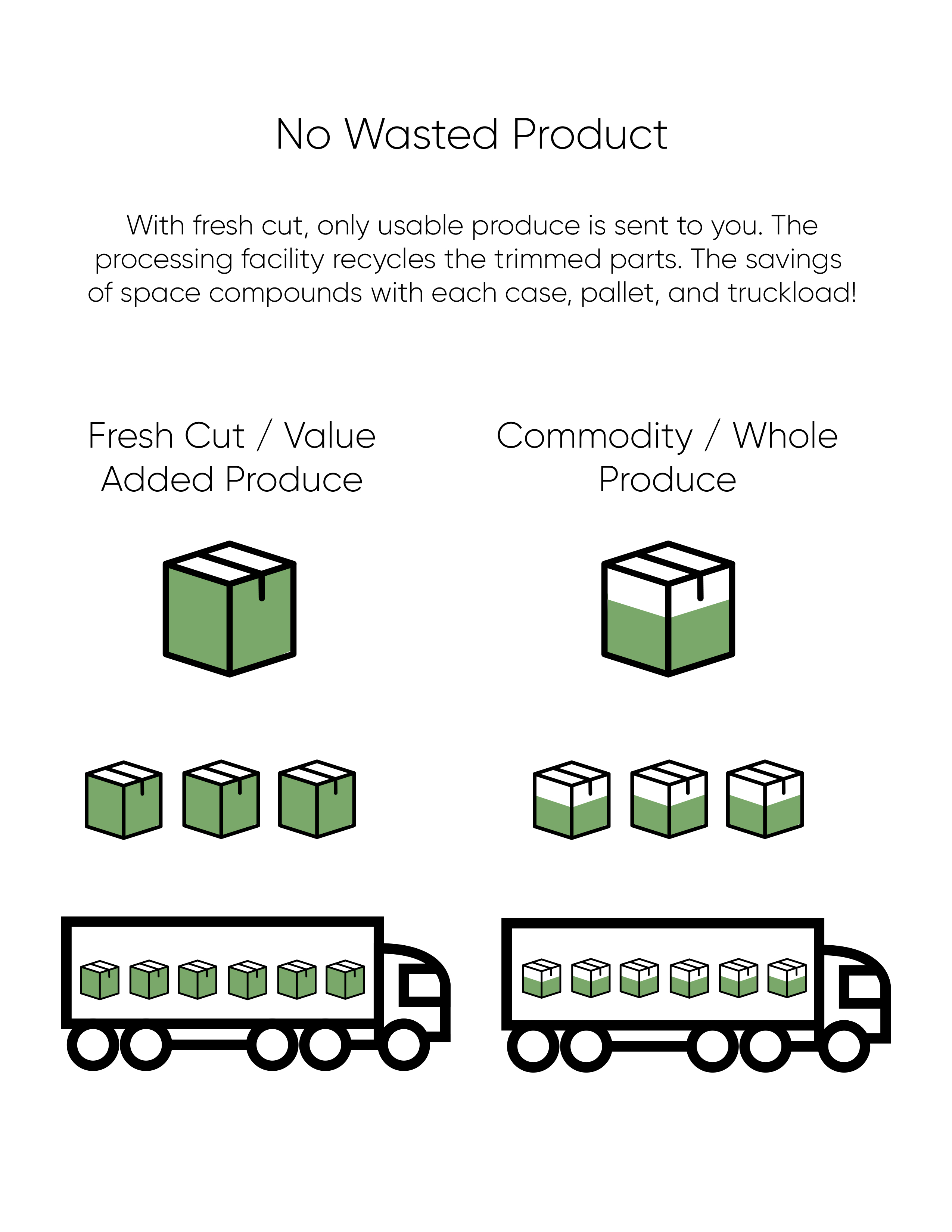

Fresh Cut Helps with Labor Concerns

Good Help is Hard to Find

With unemployment at a low, finding reliable labor for entry level or minimum wage positions is becoming harder. Fresh cut product helps remove some of the labor of preparing fresh items.

Labor Rates are Climbing

At the same time, labor rates are climbing, and you don’t want to overwhelm customers with higher prices. Fresh cut not only removes some prep work, but as we mentioned before, this is one way to bring stability to planning, budget, and operations which ultimately saves money.

Reduced Labor from Less Prep Time

The time spent on labor is reduced when you reduce the amount of labor going on in your kitchens. Fresh cut is an easy first step to making your prep time lean and efficient.

Less Equipment and Space is Required in the Kitchen

You can spend less on equipment, counter, and storage space when product is ready to use vs. a bulky whole product that requires space and time to prep.

Reduced Personnel Training

Another cost is training, and when the product is not needing to be cut by kitchen staff, there is less need to train staff on cutting fresh product.

Reduces Chances of Injury

One great benefit of fresh cut is that you can reduce the chances of injury from knives or from lifting a large amount of heavy boxes. Mitigating injury also decreases money spent on workman’s comp.